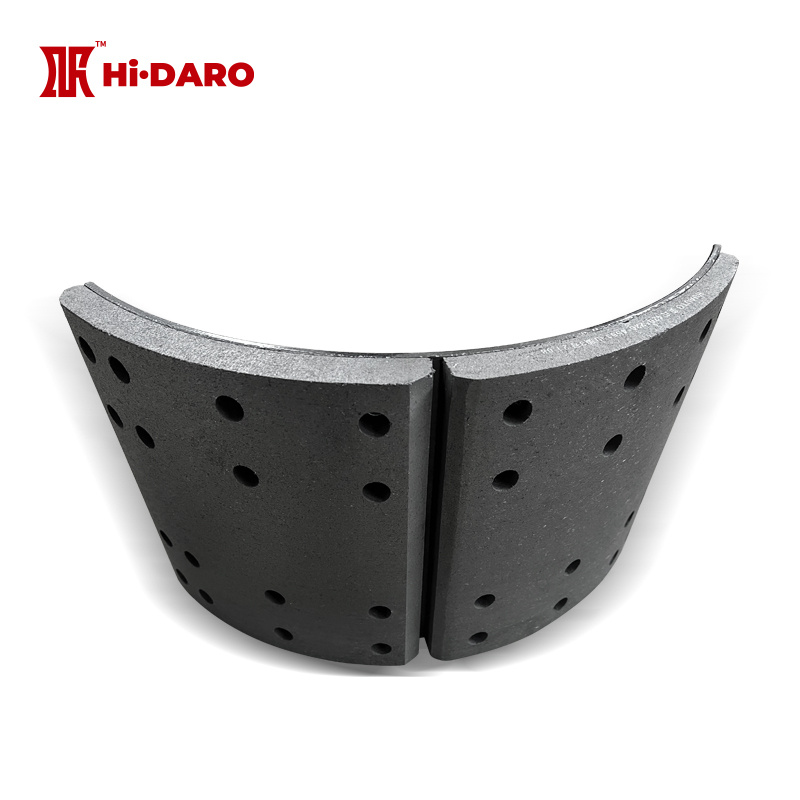

Products DescriptionBrake is one of the most frequently used parts of the vehicle. The performance of the brake pad plays a decisive role in the safety of the vehicle. Trailer drum brake pads produced by DARO are special for trailers.

Contact Now

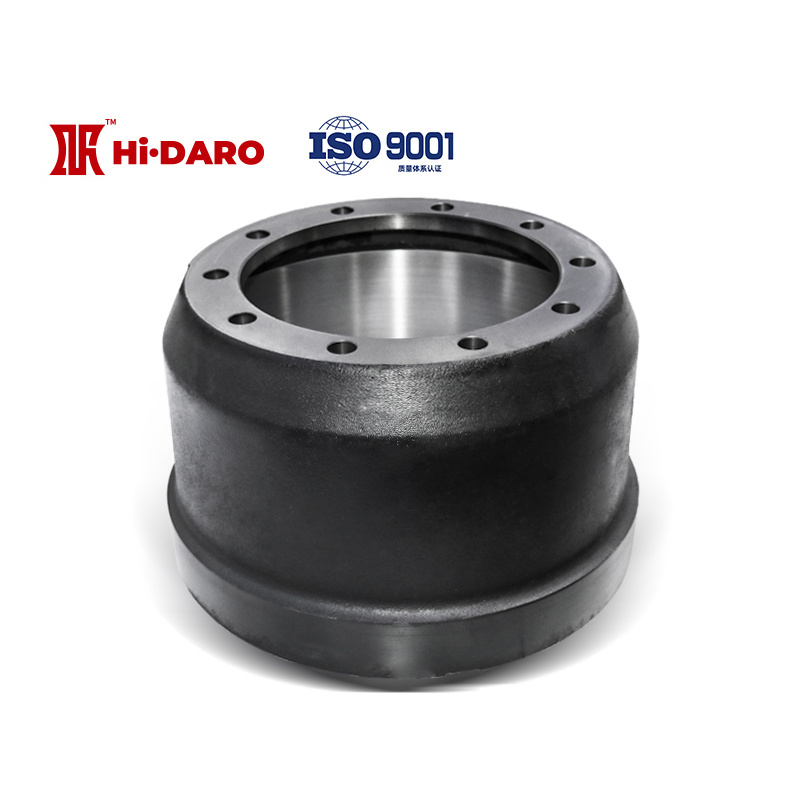

Products DescriptionThe trailer brake drum has reliable quality, faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.

Contact Now

Products DescriptionDARO sold 16T Brake pads for trailers selected high-quality raw materials, from material selection to processing are strictly controlled quality inspection. Using advanced manufacturing process, nit-picky details, with stable friction performance, low wear, low high temperature decline, small wear to the brake drum, to ensure product safety and reliability.

Contact Now

Products DescriptionDARO trailer axle Brake Drum:Select raw materials -——Using lighter weight high-strength alloy raw materials to reduce product weight.Mature process -——heat treatment and tempering, better wear resistance, good fit with brake shoes, improve driving safety.Reliable quality —— faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection -——assembly line production, single inspection out of the warehouse, stable and reliable quality.DARO trailer axle Brake Drum is suitable for 13T-16T drum axle.

Contact Now

Products DescriptionDARO disc brake trailer axles:Easy maintenance: the brake pads of the disc axle are directly outside, you can see the brake pads or other structures very intuitively, and you can see whether you need to maintain the axle without disassembling it, if you need to maintain it, you only need to replace the brake pads.Light weight and strong thermal attenuation ability: disc axle banned 360° brake drum, the weight has been greatly improved; At the same time, after the installation of the disc axle, there is no need to install the water sprinkling device, which can further increa

Contact Now

Products DescriptionDARO truck trailer brake pads have high wear, high temperature and corrosion resistance to ensure reliable braking capability under extremely high friction and temperature, fast heat dissipation, sensitive braking, low wear and low high temperature decay. Advanced manufacturing technology, high product precision, stable quality, from material selection to processing, strict control of quality inspection, to ensure product quality.The performance of brake pads is a key factor to measure its quality.

Contact Now

Products DescriptionDARO's Brake pads for trailers at wholesale prices:1, high friction coefficient: this is a key factor in determining the size of brake pad braking force. Too low friction coefficient will lead to poor braking performance, weakness, and too long braking distance, while too high friction coefficient will cause wheel lock, direction loss and other problems.2, good high temperature resistance: brake pads will produce high temperature when working.

Contact Now

Products DescriptionSelected raw materials - the use of lighter weight high-strength alloy raw materials to reduce the weight of the truck Brake Drum product.Mature process - heat treatment and tempering, stronger wear resistance, good fit with brake shoes, improve driving safety.Reliable quality - faster thermal conductivity, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection - assembly line production and assembly, individual inspection and warehousing, stable and reliable quality.The use of global superior forging technology, to

Contact Now

Products DescriptionCompared with ordinary semi-trailer axle, DARO 13T lowbed trailer axle with brake adopts 20Mn2 seamless steel tube with higher wall thickness. Not only the axle beam, but also the wheel hub, brake drum, friction plate and other accessories of the low flat truck axle are also dedicated, and the strength, toughness and wear resistance are all fully up to standard. Online + offline double quality inspection + ultimate performance test to ensure that the axle provides stable performance in complex environments.ModelMax.

Contact Now

Products DescriptionDARO 13T German type custom trailer axles uses high-strength 20Mn2 seamless steel pipe as raw material. After more than ten production processes, the strength and toughness meet the standard, which can provide better load-bearing performance. Bearings, wheels, brake drum parts are selected from well-known brands in the industry, have passed the market for many years of postgraduate examination, quality and performance are stable and reliable.ModelMax.

Contact Now

Products DescriptionThe DARO trailer axle with disc brake has a lighter weight, and the 360° brake drum is banned, which greatly improves the weight. At the same time, after the installation of the disc axle, there is no need to install the water sprinkling device, which can further increase the load of the vehicle.

Contact Now

Products DescriptionAdvanced manufacturing process, Brake Pad detail nitpicking, to ensure product safety and reliability.Bear high load, high friction coefficient, more stable braking effect, suitable for commercial models.Select high quality materials, from material selection to processing, strict quality control, to ensure product quality.Faster warmth dissipation and touchy brakingTrailer specific brake is stable, secure and stable, put on resistance and constructing resistanceStable friction performance, low wear, low e

Contact Now

Products DescriptionQuality assurance - 13T External Axle Series 100% online testing + manual quality inspection, to ensure that the quality is strictly in line with industry standards.Strong environmental adaptability -- through strict ultimate performance test, can adapt to complex operating environment.Rational optimization of production process, 13T External Axle Series axle consistency, interchangeability stronger.Simplified maintenance process, more convenient replacement, reduce users' outage time, improve operation efficiency.Multi-layer sealing structure, plus

Contact Now

Products DescriptionThe american type Independent trailer axle produced by DARO Group adopts 20Mn2 high-strength alloy seamless steel pipe as the raw material, with both strength and toughness reaching the standard and stronger load-bearing capacity. Brake drum, wheel hub, bearing, brake pads, bolts and other parts are used in the industry's leading brands, stable and reliable quality. Entering the market for more than 20 years, customers are highly praised.ModelMax.

Contact Now

Products DescriptionDARO 13T American type Trailer axle Beam is made of 20Mn2 high-strength alloy seamless steel pipe with standard wall thickness of 11mm and diameter width of 150*150mm. Integrated hot rolling molding process eliminates manual welding, and has stronger bending and torsional resistance and load-bearing capacity. Ensure the efficient operation of vehicles for a long time.ModelMax.

Contact Now

Products DescriptionDARO 13T commercial trailer axles uses 20Mn2 high-strength alloy seamless steel pipe as raw material, solid quality and performance, product quality is more reliable; Special baking process is added on the surface. The double layer treatment of primer + top coat can improve the corrosion resistance by 4 times, greatly improve the protection force, and effectively extend the service life of the axle.

Contact Now

Products DescriptionGood heat dissipation, high roundness, Brake Hub high speed balance, reduce hub wear.Denser low pressure casting process, with T6 heat treatment, not easy to deformation.Impact resistance melting, structure strengthening design, stronger product bearing capacity.Selected lightweight materials, lighter hub weight, minimize gasoline consumption.Good warmness dissipation, excessive roundness, excessive velocity balance, decrease hub wear.Denser low stress casting process, with T6 warmth&n

Contact Now

Products DescriptionDARO 13T trailer leaf spring suspension is made from high quality silicon manganese spring steel and is made with a high heat treatment process. It has higher strength, elasticity and hardenability. While ensuring high strength, it can fully improve the product's toughness and seismic performance.

Contact Now

Products DescriptionThe DARO Group's german type trailer axles include 12T, 13T, 14T, 16T and 18T tonnage, which can be customized to meet customer requirements. DARO has its own factory, and the entire production process is subject to unified and strict quality control, from the internal mechanical properties of steel to the external dimensional accuracy, fully in line with national standards. The quality inspection process starts from raw materials, covering every link of design, production and testing.

Contact Now

Products DescriptionThermal attenuation resistance - excellent thermal stability.

Contact Now

Products DescriptionThe DARO 13t low bed trailer axle with hubs is designed to fully combine the transportation requirements of low flat trailer, and the wheel end size is smaller, further reducing the center of gravity of the vehicle, and better transportation stability. The raw material selection of high-strength 20Mn2 seamless steel pipe, shaft body after special thickening treatment, higher strength, perfect for the various transportation needs of low plate semi-trailer. Wholesale price, more cost-effective.ModelMax.

Contact Now

Products DescriptionUtility trailer axles,no need to disassemble the wheel hub, and the replacement and maintenance of components such as brake pads are more convenient. Higher cost performance, reduced fuel consumption, saved comprehensive vehicle costs. 100% online testing+manual quality inspection, ensuring strict compliance with industry standards and guaranteed qualityModelMax.

Contact Now

Products DescriptionCarefully chosen material——Selected excessive first-rate uncooked materials, brake shoe repair kits first-rate pass, secure performance, lengthy carrier life, really worth purchasing.Size standard—— Source manufacturers, manufacturing method in strict accordance with the trendy implementation, uniform size, enhance the utility accuracy.Quality stability——The product has exact tension and toughness, brake shoe repair kits anti-aging, anti-corrosio

Contact Now

Products DescriptionDARO low-bed trailer axles with brakes is made of 20Mn2 high-strength alloy seamless steel pipe with high strength, high toughness and smaller diameter of the upper wheel end. It belongs to a special type of axle, which is different from ordinary axle in appearance and performance. All accessories are also dedicated, such as brake drums, brake pads, bearings, bolts, etc., strength, toughness, wear resistance and other indicators are also higher.ModelMax.

Contact Now